ERIKS started the distribution of O-Rings in 1952. Since then ERIKS has become a world leader in the production and distribution of O-Rings and elastomeric seals.

ERIKS seals are manufactured in state-of-the-art production facilities with quality control procedures in-place to satisfy even the most demanding quality requirements. Our inventory policies insure that the widest assortment of o-rings are readily available when you need them the most.

In addition, we offer technical expertise to provide you with the best solution to meet your seal requirements. It is this level of technical experience that allows us to handle specialized application requirements, whether it is for large quantities of o-rings or a small quantity engineered prototypes. ERIKS offers not only a broad range of products but a broad range of services as well. When you need seal solutions ERIKS will be standing by to offer superior technical support, customer service, and inventories to satisfy your seal requirements.

Applications

The O-ring is one of the most popular seal

choices because:

- The O-ring is cost effective in purchase price and the cost to machine the seal groove is relatively low.

- As a bi-directional squeeze seal, the O-ring can be used in an extremely wide variety of successful applications, both static and dynamic.

- The O-ring material allows for maximum stretch or compression and is therefore quite easy to install, generally requiring no special tools.

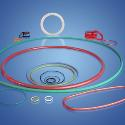

Static Applications

There are four varieties of static applications:

- Axial

The O-ring cross section is squeezed axially in the groove similar to a flat gasket. (figure 1) - Radial

The O-ring cross section is squeezed radially in the groove between the inside (ID) and outside (OD). (figure 2) - Dovetail

The O-ring is also axially squeezed in a dovetail groove. The groove design allows the O-ring to be retained in the face seal during assembly and maintenance. This is beneficial for special applications where the O-ring has to be fixed by the groove e.g. a lid which opens regularly. (figure 3) - Boss Seals

The O-ring is used for sealing straight thread tube fittings in a boss. A boss is a cylindrical projection on a casting or forging. The end of that projection is machined to provide a flat, smooth surface for sealing. Straight threads used with an O-ring provide a better seal than tapered threads used alone. (figure 4)

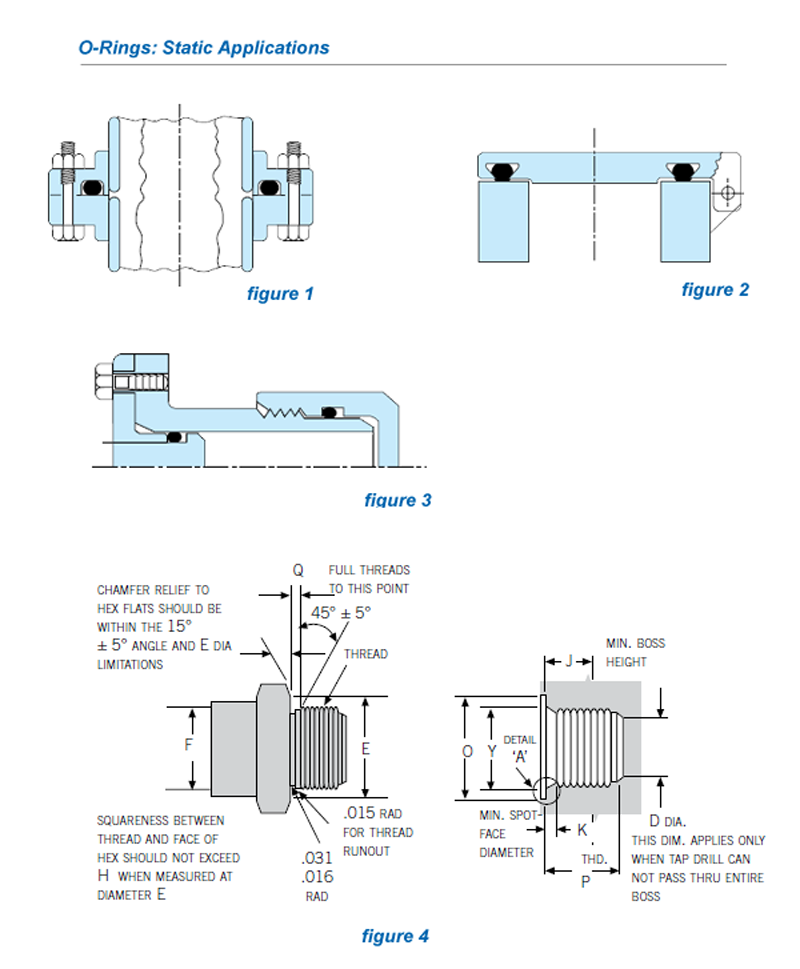

Dynamic Applications

There are three varieties of dynamic applications:

- Reciprocating

Reciprocating seals refer to seals used in applications that slide back and forth. This motion introduces friction, which creates design considerations different from those of static seals. The O-ring may be housed in a groove (rod seal) in the cylinder wall instead of a groove in the piston surface (piston seal) without any change in design limitations or seal performance. (figure 5) - Oscillating

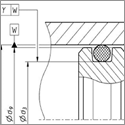

Oscillating applications are those seeing both rotary and reciprocating movement. A valve spindle is an example of an oscillating application. (figure 6) - Rotary

Rotary seals refer to seals used in applications that rotate. (figure 7)