The O-ring has become the world's most popular and versatile seal due to its simple shape, low space requirements and its availability in a vast selection of sizes and compounds to meet every industrial requirement.

O-rings are bi-directional seals, circular in shape and cross section. O-rings are generally made of an elastomeric material, but may be made of other materials such as PTFE or metal.

An o-ring seals through the deformation of the seal material by installation and media pressure to close off the gap between mating components. Higher system pressures can cause deformation through the gap, known as extrusion, resulting in seal failure. Choosing a harder seal material or installing back-up rings to support the O-ring may alleviate this problem.

Materials

| Material |

Temp Range |

Comments |

ERIKS Gereral Compound |

|---|---|---|---|

| THERMOSET ELASTOMERS | |||

| Nitrile (NBR), Buna N | -40C (-40F) to 121C (250F) | General service | E36626 (70) E366890 (90) |

| Hydrogenated Nitrile (HNBR), HSN | -40C (-40F) to 150C (302F) | General service | E88600 (70) E88690 (90) |

| Ethylene Propylene (EPR, EPDM) |

-55C (-67F) to 150C (302F) | Water and solvent service | E55641A (70) |

| Polychloroprene (CR) Neoprene® | -40C (-40F) to 121C (250F) | Refrigerants and water service | C70 |

| Silicone(VMQ) | -59C (-75F) to 230C (446F) | High temperature service | E714177 (70) |

| Fluorosilicone(FVMQ) | -60C (-76F) to 180C (356F) | Military fuel service | F70 |

| Polyacrylate (ACM/AEM) Vamac® | |||

| Fluorocarbon (FKM) Viton®, Fluorel®, Technoflon® |

-20C (-4F) to 200C (392F) | Chemical and high temp service | E51414 (75)E514320 (90) |

| TFE/P (FEPM) Aflas® |

-20C (-4F) to 200C (392F) | Chemical and high temp service | E22338 (80) |

| Perfluoroelastomer (FFKM) Kalrez®, Chemraz® |

-20C (-4F) to 300C (572F) | Extreme chemical and high temp service | Kalrez® |

|

|||

| THERMOPLASTIC ELASTOMERS | |||

| Polyurethane (AU, EU) |

-40C (-40F) to 82C (180F) | Hydraulic service | PUR90 |

| Thermoplastic Polyester (TPC-ET) Hytrel® | |||

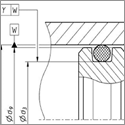

Sizes

The tables below list approximately 2000 O-ring sizes in order by inside diameter. These O-ring sizes correspond to US Standard AS568, British Standard, Swedish, as well as many common metric sizes according to DIN and ISO standards. Most of these sizes are readily available from ERIKS stock in the following materials:

- Nitrile NBR

- Fluoroelastomer FKM (Viton®) 75 and 90 Shore A

- Perfluoroelastomer FFKM (Kalrez®) 75 Shore A

- Ethylene-propylene EP, EPDM 70° Shore A

- Silicone VMQ 70 Shore A

- PTFE

- Teflex FEP/Viton®

- Teflex FEP/VMQ

Our list of standards is continually being expanded. Please contact us for additional sizes not indicated here.

| Standard O-ring Sizes | |

|---|---|

| 000 Series | 004 to 050 cross section Diameters w = .070 ± .003 inches, w = 1,78 ± 0,08 mm |

| 100 Series | 102 to 178 cross section Diameters w = ..103 ± .003 inches, w = 2,62 ± 0,08 mm |

| 200 Series | 201 to 285 cross section Diameters w = 139 ± .004 inches, w = 3,53 ± 0,10 mm |

| 300 Series | 309 to 395 cross section Diameters w = .210 ± .005 inches, w = 5,33 ± 0,13 mm | 400 Series | 425 to 475 cross section Diameters w = .275 ± .006 inches, w = 6,99 ± 0,15 mm |

| 900 Series | |