Whatever market you are in, ERIKS has the knowledge and experience to focus on your specific demands and deliver tailored solutions that meet your needs.

We offer a wide range of sealing solutions from metal components to high performance elastomers and plastics. Our application engineers posses an in-depth understanding of sealing products and their unique applications. We represent the world's most respected seal and polymer manufactures which allows us to provide our customers with the most objective assessment of the features and benefits of available products that meet their specific needs, not ours. If we cannot find the right product for your application we will work with you to make it.

ERIKS offers rolling element bearings designed to meet your specifications. Our state-of-the-art bearing manufacturing facility enables us to offer the highest level of quality. In addition to our own in-house manufacturing, we source bearings domestically and globally from the highest quality manufacturers, all of which are ISO/QS/TS certified.

Our engineers and technical specialists will go through the complete development process with you to ensure the correct material and process is selected for your specific application. In addition, we have an in-house materials development laboratory that has developed many of unique to meet the specific needs of a wide range of applications.

ERIKS is the world's largest supplier of hydraulic and pneumatic seals and one of the only who can offer both US and metric standard parts in stock. Our knowledgeable and dedicated staff can help you with your product and logistical requirements.

ERIKS offers the most comprehensive range of gasket materials and sizes to meet even the most challenging applications. Hundreds of semi-finished components and standard seals in various materials and designs are in stock and ready to be shipped to our customers.

Rotary seals perform two basic functions. The primary function is to retain the lubricant in the system. The secondary purpose is to exclude external contaminants such as water and dirt. Organizations face particular challenges with an increasing number of specialty lubricants appearing on the market today, making seal design and the selection of seal material especially important.

ERIKS seals are manufactured in state-of-the-art production facilities with quality control procedures in-place to satisfy even the most demanding quality requirements. Our inventory policies insure that the widest assortment of o-rings are readily available when you need them the most.

In addition, we offer technical expertise to provide you with the best solution to meet your seal requirements. It is this level of technical experience that allows us to handle specialized application requirements, whether it is for large quantities of o-rings or a small quantity engineered prototypes. ERIKS offers not only a broad range of products but a broad range of services as well. When you need seal solutions ERIKS will be standing by to offer superior technical support, customer service, and inventories to satisfy your seal requirements.

Spring energized seals excel in applications with high-speeds, wide temperature ranges and those with corrosive media. The ERIKS brand of spring energized seals, branded SE Seals, are manufactured in our state-of-the-art e-Fab facility.

The SE Seal design is based on three principles:

ERIKS provides a range of surface modification processes to reduce friction or surface contamination.

In addition to the SuMo process which physically and chemically modifies the surface, ERIKS provides additional processes which may significantly improved dynamic performance. DepoPar polymer coatings can be vacuum deposited in thicknesses from 0.003 to 0.1 on many surfaces. The Ultralube™ WS2 coating has demonstrated reduced friction and can eliminate galling on metal parts.

Advanced engineered plastics are increasingly used to replace expensive or heavy metal components. Starting from just a sketched design, ERIKS can manufacture plastic products precisely as per specification. Quantities can vary from a few items to large series depending on your needs.

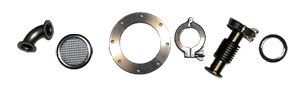

ERIKS provides many specialty metal products and related services designed to provide solutions to the most demanding industrial sealing and wear applications. There are many applications that require metallic rings for their sealing application, including applications for very low leakage, high temperature and high pressure.

ERIKS offers a wide range of components for high vacuum applications.

Wherever advantage you are seeking in your business, ERIKS' know-how can help you achieve it. Our passion for technology and unbiased approach extends from supplying simple parts to helping you improve efficiency, increase performance and lower costs.

Contact us today, we love to help our customers solve their sealing issues.

© 2024 ERIKS Seals and Plastics, Inc.